JFTOT® IV

The Worldwide Recognized Leader of Jet Fuel Thermal Oxidation Testing

Globally Recognized Standard for Jet Fuel Thermal Oxidation Testing

PAC’s Alcor JFTOT® IV is the globally recognized standard for jet fuel thermal oxidation testing with a worldwide installed base of over 1,000 instruments. With JFTOT® IV, PAC brings an industry-leading product with enhanced safety features and simplified operational capabilities in a smaller, streamlined package that significantly increases operator productivity.

With the Next Generation JFTOT® IV, PAC brings an industry-leading product and adds enhanced safety features and simplified operational capabilities in a smaller, streamlined package that significantly increases operator productivity.

Significantly Improve Your Operations

The Alcor JFTOT® IV helps you significantly improve your operations, in an easy, safe way while strictly following ASTM D3241, IP 323, and ISO 6249 test methods.

Top Reasons to Choose JFTOT® IV

Increased Lab Productivity by 25%

Enhanced Safety

Simplified Operation

Ease-of-Use

Get the Brochure

Learn more about the recognized standard for jet fuel thermal oxidation testing.

Get the Brochure

Get Started

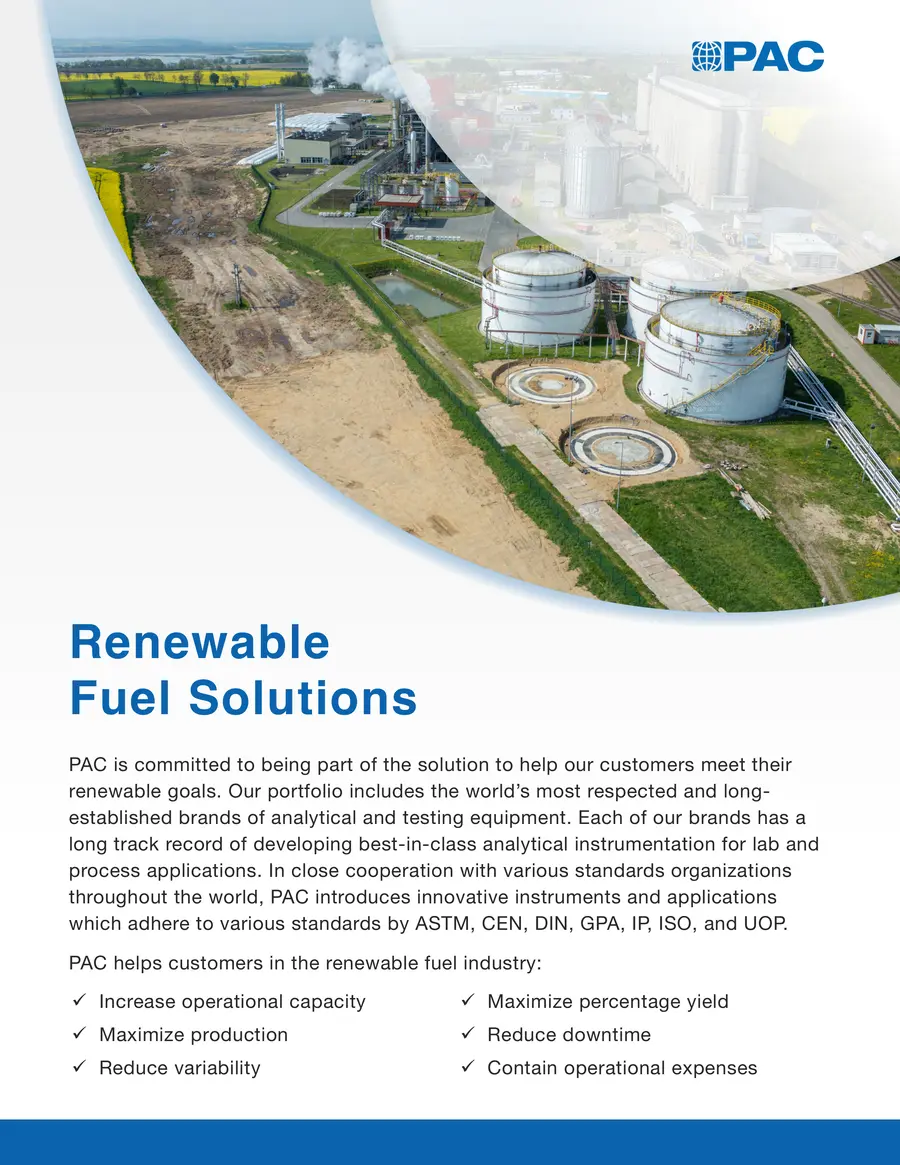

Renewable Fuel Testing Solution

JFTOT has enhanced safety features and simplified operational capabilities through accurate and reliable jet fuel analysis, with a small-footprint design.